- TheCobotReport

- Posts

- #08 TheCobotReport

#08 TheCobotReport

Automated Metal Bending, Industrial Efficiency, Smart Automation...

Hey Innovators,

The robotics revolution is here, and it’s shaking up industries faster than a cobot on an assembly line. From surgical precision in operating rooms to game-changing automation in manufacturing, robotics is reshaping the future. Companies like RTX, Stryker, and Medtronic are not just riding the wave, they’re building it. This week, we’re diving into the numbers, tech, and strategies that make these automation pioneers stand out, plus a look at how cobots are transforming what’s possible in the workplace. Ready to explore the cutting edge? Let’s get to it.

In this week’s email…

Quick Hit: Robotics Revolution: How RTX, Stryker, and Medtronic Are Leading the Automation Surge

Movers & Shakers:

AMADA's HRB 8025: Pioneering 24/7 Automated Bending with Cobot Synergy

Compact Powerhouse: Elephant Robotics Unveils the Versatile myCobot Pro 630

Graduate Corner: Vision-based Manipulation of Transparent Plastic Bags in Industrial Setup

In the news…

Nexperia & Synapticon Partnership to enhance integrated motion devices

ABB Leverages AI to revolutionize industrial automation

MIT's LucidSim System Bridges Simulation & Reality for advanced robot training

Nala Robotics Introduces BIRYANIMAN the world's first robotic Biryani chef

QUICK HIT:

How RTX, Stryker, and Medtronic Are Leading the Automation Surge

The robotics sector is experiencing unprecedented growth, with projections indicating a compound annual growth rate (CAGR) of 14.7%, aiming to reach $283.19 billion by 2032. This surge is propelled by advancements in artificial intelligence, machine learning, and autonomous systems, significantly impacting sectors such as healthcare.

RTX Corporation (RTX): Specializing in aerospace, RTX reported sales of $20.1 billion in the third quarter of 2024, marking a 6% increase from the previous year. The company's backlog reached a record $221 billion, with $131 billion attributed to commercial sectors.

Stryker Corporation (SYK): A leader in medical technology, Stryker reported a 9.7% rise in quarterly revenue to $5.24 billion as of March 31, 2024, surpassing estimates of $5.10 billion. The company raised its full-year profit forecast, now expecting an annual profit per share between $11.85 and $12.05, up from the previous range of $11.70 to $12.00. Stryker's advancements in robotic-assisted surgical systems are contributing to this growth, addressing the increasing demand for minimally invasive procedures.

Medtronic plc (MDT): As a global healthcare technology provider, Medtronic reported fiscal 2025 first-quarter revenue of $7.92 billion, a 2.8% year-over-year increase, exceeding analysts' forecasts. The company raised its full-year organic revenue growth forecast to 4.5% to 5%, up from the previous 4% to 5%. Medtronic's innovations in robotic-assisted surgery and other medical technologies are driving this upward trajectory.

These companies exemplify the transformative impact of robotics across various industries, highlighting the significant role of automation in shaping the future of technology and business.

MOVERS & SHAKERS:

1 . AMADA's HRB 8025: Pioneering 24/7 Automated Bending with Cobot Synergy

Image Courtesy of Canadian Metal Working

AMADA AMERICA has introduced the HRB series press brakes, designed for versatility and user-friendliness. When integrated with AMADA's Collaborative Robot (Cobot) System, the 88-ton HRB 8025 press brake transforms into a fully automated bending system, enabling seamless transitions between automated and manual operations.

Technical Specifications of HRB 8025:

Press Capacity: 800 kN (approximately 88 tons)

Bending Length: 2,600 mm

Stroke Length: 250 mm

Open Height: 520 mm

Approach Speed: 150 mm/s

Bending Speed: 15 mm/s

Return Speed: 150 mm/s

Machine Mass: 6,300 kg

Key Features:

AMNC 3i Control: Equipped with an 18.5-inch multi-touchscreen interface, the HRB 8025 offers intuitive operation, including a 'Lite' mode for simplified programming.

SGrip 6-Axis Backgauge System: This system ensures precise positioning of the workpiece, enhancing bending accuracy and repeatability.

Energy-Efficient Hybrid Drive System: The hydraulic circuit operates "on demand" during the bending cycle, reducing power consumption by at least 20% compared to conventional press brakes without an inverter.

Cobot System Integration:

The integration of the Cobot System with the HRB 8025 press brake offers several advantages:

Drag-and-Drop Programming Interface: Operators can efficiently set up programs directly at the machine, streamlining the bending process and reducing setup times.

Direct Blank Handling: The cobot can pick up blanks directly from a standard pallet, eliminating the need for manual loading onto a gauging table and enhancing operational efficiency.

This integration exemplifies advancements in automated bending solutions, providing manufacturers with the capability to operate continuously and adapt to varying production demands.

Investors take note: AMADA's commitment to innovation in automation and energy efficiency positions the company favorably in the evolving manufacturing landscape. The development of advanced systems like the HRB 8025 press brake with Cobot integration reflects a strategic focus on meeting industry demands for precision and efficiency. Such initiatives are likely to enhance AMADA's market competitiveness and could positively influence its financial performance.

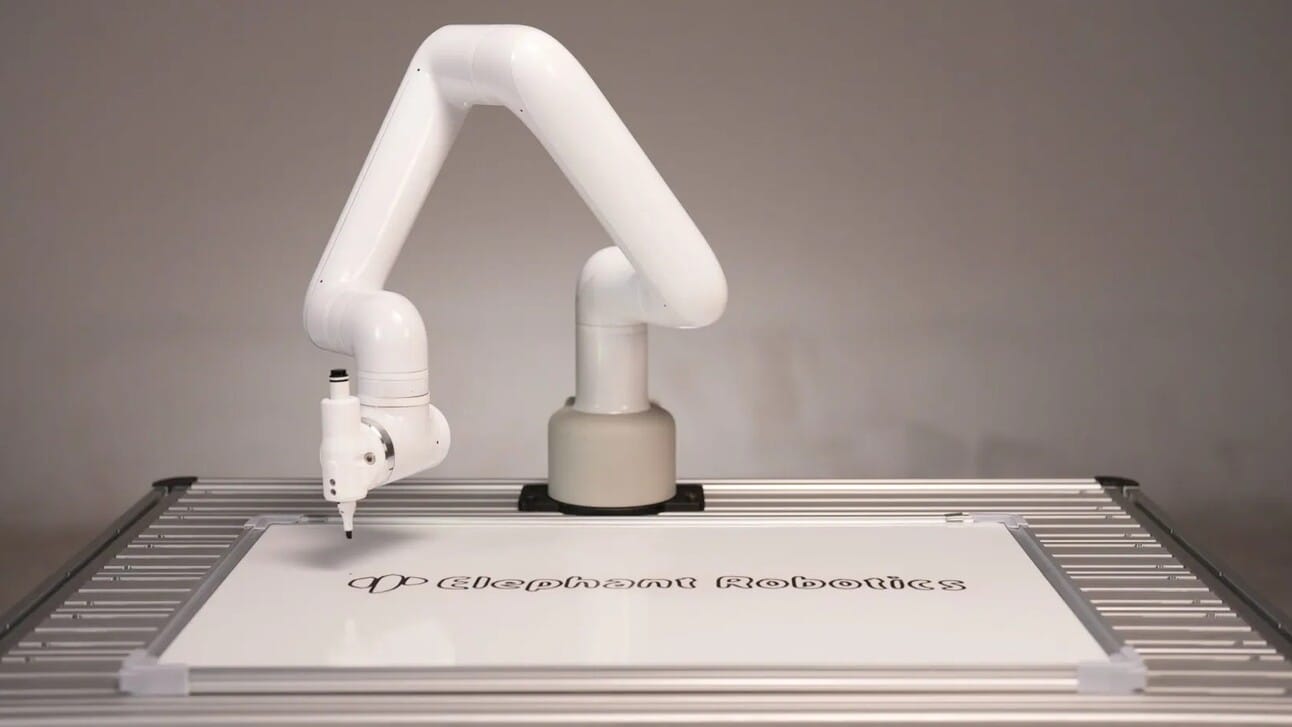

2. Compact Powerhouse: Elephant Robotics Unveils the Versatile myCobot Pro 630

Image Courtesy of Elephant Robotics

Elephant Robotics has introduced the myCobot Pro 630, a compact six-axis robotic arm designed for commercial and educational applications. Building upon the myCobot Pro 600, this upgraded model offers enhanced performance and versatility.

Advantages:

Compact Design: The myCobot Pro 630 is 30% smaller than its predecessor, the myCobot Pro 600, allowing for seamless integration into various production environments without compromising performance.

High Payload Capacity: Despite its reduced size, it maintains a payload capacity of up to 2 kg, making it suitable for handling a wide range of tasks.

Enhanced Precision: With a repeatability of ±0.1 mm, the robotic arm ensures high accuracy, essential for applications requiring meticulous movements.

User-Friendly Interface: Equipped with a customized Linux operating system and proprietary Roboflow control software, it supports uninterrupted 24/7 applications and offers an intuitive user experience.

Versatile Connectivity: The myCobot Pro 630 provides various hardware connectivity options, including USB, EtherNet/IP, RS485, and 24V-I/O interfaces, catering to diverse robotic application development needs.

Key Features:

All-in-One Design: The integrated structure maximizes workspace utilization and seamlessly fits into various production environments. An anti-collision detection function, based on a precise dynamic model, ensures safe human-robot collaboration.

Advanced Control System: The robotic arm features a customized Linux operating system and proprietary Roboflow control software, supporting uninterrupted 24/7 applications.

Software and Programming Support:

The myCobot Pro 630 supports multiple programming languages, such as Python and C++, and is compatible with platforms like Android, Windows, macOS, and Linux. It also integrates with ROS1, ROS2, and Gazebo simulation environments, providing open-source control driver files and basic RVIZ and MoveIT use cases.

Application Scenarios:

This robotic arm is suitable for various applications, including 3D unstructured visual sorting, 2.5D palletizing sorting, robotic writing and painting, and compound robot mobile inspection. It supports integration with peripheral devices such as 3D cameras, recognition software, actuators, industrial PCs, and mobile AGVs, meeting the customized application needs of different users.

Who Is It For?

The myCobot Pro 630 is designed for professionals and educators seeking a compact, versatile robotic arm for tasks requiring precision and adaptability. Its user-friendly interface and broad compatibility make it suitable for research institutions, educational settings, and industries aiming to integrate automation into their workflows.

Investors take note: Elephant Robotics' development of the myCobot Pro 630 demonstrates a strategic focus on innovation and adaptability in the robotics industry. By enhancing performance while reducing size, the company addresses the growing demand for efficient and versatile robotic solutions. This approach positions Elephant Robotics favorably in the competitive robotics market, potentially leading to increased market share and financial growth.

GRADUATE CORNER:

Vision-based Manipulation of Transparent Plastic Bags in Industrial Setup

F. Adetunji , A. Karukayil, P. Samant, S. Shabana, F. Varghese, U. Upadhyay, R. A. Yadav, A. Partridge, E. Pendleton, R. Plant, Y. Petillot, M. Koskinopoulou

The School of Physical and Engineering Sciences,

Heriot-Watt University, Edinburgh, UK.

arXiv:2411.09623 14 Nov 2024

This week's spotlight falls on a groundbreaking solution for handling transparent plastic bags in industrial setups, a challenge previously considered too intricate for automation. Developed under the Industry 4.0 paradigm, the system integrates cutting-edge AI, robotics, and vision systems to achieve the following:

Vision-Based Detection: Leveraging Convolutional Neural Networks (CNNs), the system identifies transparent plastic bags under varying conditions, overcoming challenges like reflections and deformation.

Robotic Precision: Using a cobot equipped with a suction cup gripper, the system achieves high precision in bag handling and placement, supported by depth sensors for 3D spatial awareness.

Efficient Cutting Mechanism: A custom-designed scalpel and linear rail ensure precise cuts without damaging the contents. The process combines vacuum-driven suction cups and smart actuation for consistent performance.

Autonomous Workflow: A full cycle integrates detection, picking, cutting, and delivery into a bulk loader, achieving a 96.8% detection accuracy and an 86% average success rate for pick-and-place tasks.

Technical Perspective: This solution highlights advancements in combining computer vision, real-time robotics, and automation, pushing the boundaries of tasks like waste management, packaging, and recycling. The successful lab implementation demonstrates its potential for scalability and real-world applications.

Takeaway for Future Engineers: The integration of deep learning, robotic dexterity, and intelligent control systems exemplifies how automation can tackle complex industrial challenges. Emerging engineers can explore further by improving adaptability to different materials, refining algorithms, or integrating with larger systems for diverse industrial needs.

Stay tuned for more insights into the transformative power of robotics and AI in reshaping industries!

Reply